Pump Power Calculation Method

Water Pumps are indispensable equipment in both industrial and daily life. The calculation of their power is a key factor to ensure their normal operation. This article will introduce in detail the methods and steps of pump power calculation, helping you to choose the right pump power.

I. Pump Power Calculation Formula

The formula for calculating pump power is:

P = pgQH / 1000

Where:

- P: Pump power (kW)

- p: Density of water (kg/m³)

- g: Acceleration due to gravity (9.81m/s²)

- Q: Flow rate (m³/s)

- H: Head (m)

II. Determining the Flow Rate

The determination of flow rate needs to consider multiple factors, including:

- Process requirements of water-using equipment

- Diameter and length of the pipeline

- Intermittency of operation

1. Determine the flow rate based on the process requirements of water-using equipment

For example, for landscape water use such as fountains, the flow rate can be calculated by filling the fountain pool 1 to 2 times per hour; for agricultural irrigation, the flow rate can be calculated by irrigating 1 to 2 times per day.

2. Determine the flow rate based on the diameter and length of the pipeline

Generally speaking, the longer the pipeline and the smaller the diameter, the smaller the flow rate; the shorter the pipeline and the larger the diameter, the larger the flow rate. In the preliminary estimation, the flow rate can be calculated according to the diameter and length of the pipeline.

3. Determine the flow rate based on the intermittency of operation

If the water-using equipment is intermittent, it is necessary to consider its working time and non-working time in a unit time, as well as the amount of water required each time it works, so as to determine the average flow rate.

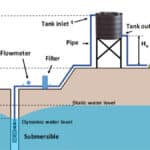

III. Determining the Head

The Pump head is the height that the pump lifts the water, which is related to the length and height difference of the pipeline.

1. Determine the head based on the length and height difference of the pipeline

Generally speaking, the longer the pipeline and the larger the height difference, the higher the head; the shorter the pipeline and the smaller the height difference, the lower the head. In the preliminary estimation, the head can be calculated according to the length and height difference of the pipeline.

2. Determine the head based on the location and height difference of the water-using equipment

If the water-using equipment is located at a higher position, the water needs to be lifted to a higher height, so the head is higher; otherwise, it is lower. In the preliminary estimation, the head can be calculated according to the location and height difference of the water-using equipment.

IV. Selecting the Pump Model

According to the calculated flow rate and head, the appropriate pump model can be selected. When selecting, the following factors need to be considered:

- The flow rate and head of the pump should meet the requirements of use

- The efficiency and energy consumption of the pump should be low

- The material and structure of the pump should meet the requirements

- The price and maintenance cost of the pump should be reasonable

V. Example of Pump Power Calculation

Suppose a fountain landscape needs a pump for water supply, the flow rate is 10m³/h, the head is 50m, and the pump efficiency is 70%. Then the pump power can be calculated according to the following steps:

1. Calculate the output power of the pump

P = pgQH / 1000 = 9.81 × 10 × 50 / 1000 = 4.9kW

2. Calculate the input power of the pump

P_in = P / η = 4.9 / 0.7 = 7kW

3. Select the appropriate pump model

According to the calculated flow rate and head and the above selection factors, a pump with more than 7KW motor can be selected. Its flow rate is 10~60m³/h, the head is 50~65m, the efficiency is high and it meets the hygiene requirements. The input power of this pump is about 7.5kW, which is close to the calculation result.

Conclusion

Pump power calculation is a key step in selecting pumps. This article introduces in detail the methods and steps of pump power calculation, and provides a calculation example, which I hope will be helpful to you.

Author introduction

My name is Kevin and I am the Product Manager for the SUNVIS Water Pump Department. I have been in the solar pumping industry for over 8 years. I specialize in Pump Design, Solar Pump System Configuration and technical support for Solar Pump Project Bidding. As a professional supplier of solar water pumps, welcome to contact us. We are happy to provide you with the best service and products.

Email: [email protected] | Whatsapp: 0086-18930406049